Olin Electric Motorsports is a student-run team that develops an electric racecar from the chassis up to compete in the Formula SAE Electric competition. I have been a member for over a year, rapidly taking on various roles and projects. As the current Powertrain Lead, I oversee the core development of the drivetrain subteam for our latest car revision, ensuring optimal performance and reliability.

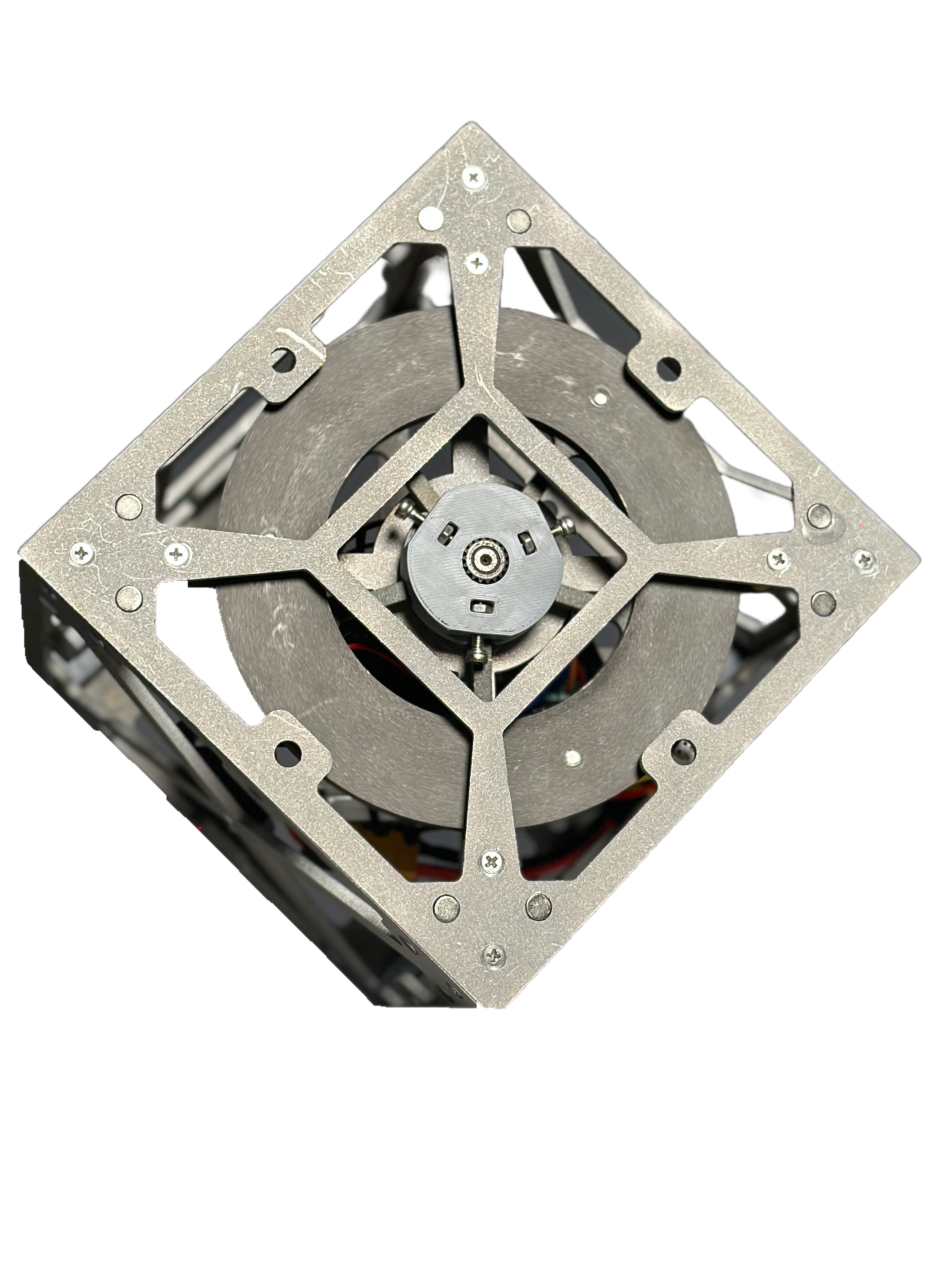

Motor and Differential Clockcage

The foundation of the drivetrain system, the clockcage ensures that the motor and differential are securely to the chassis while resisting chain forces. A 2 plate design chosen over a common 4 plate design in order to reduce tolerance stack up, design simplicity, and ease of serviceability.

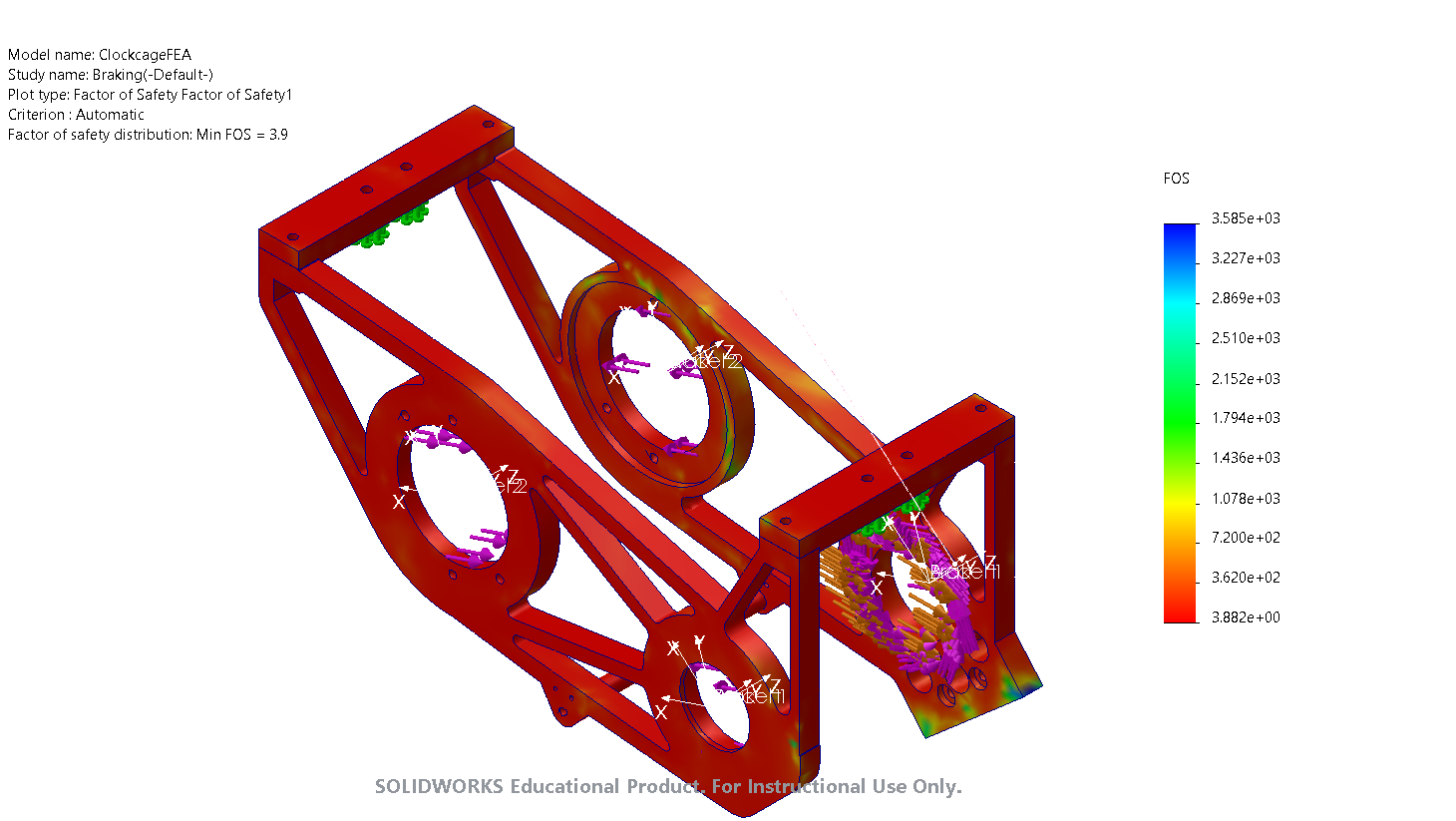

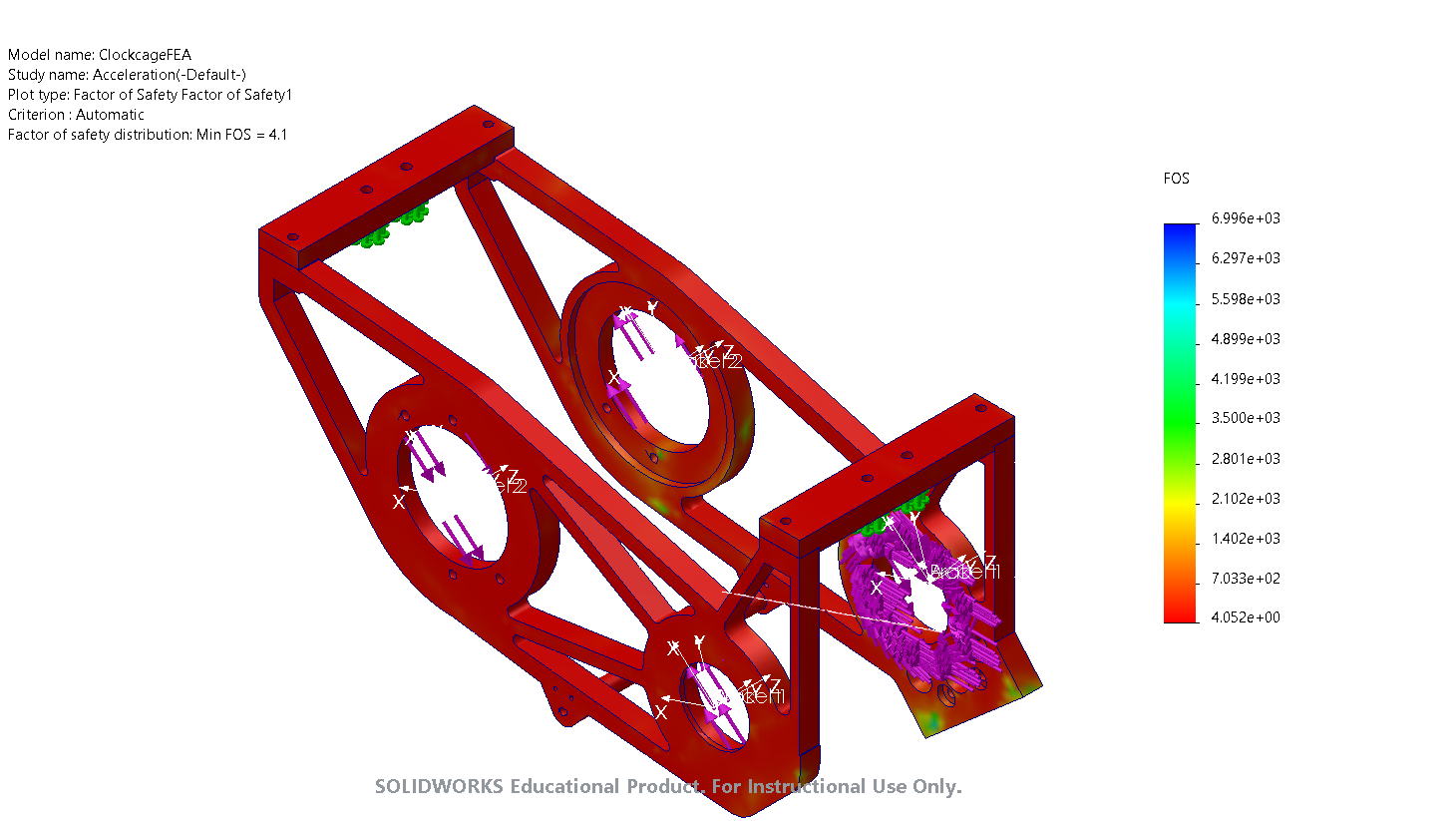

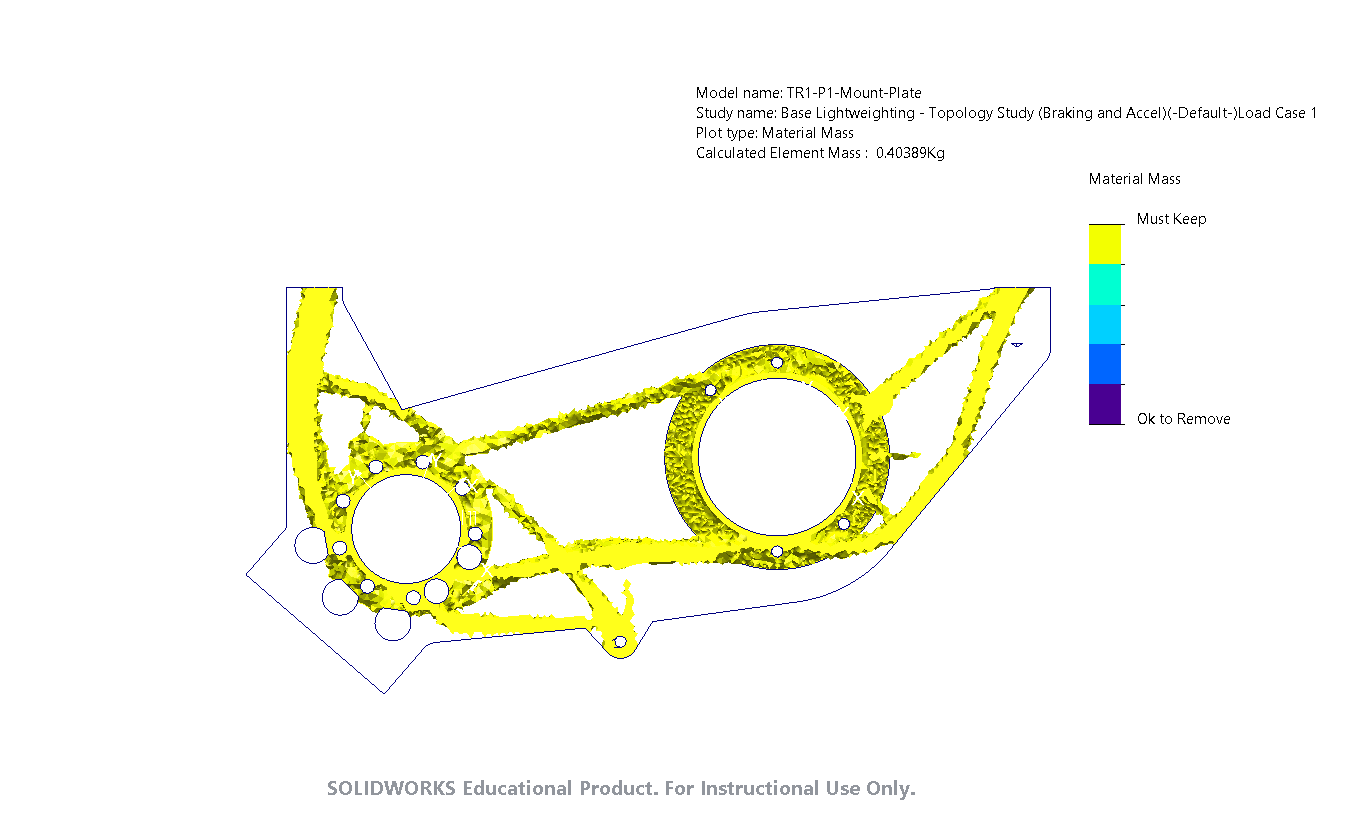

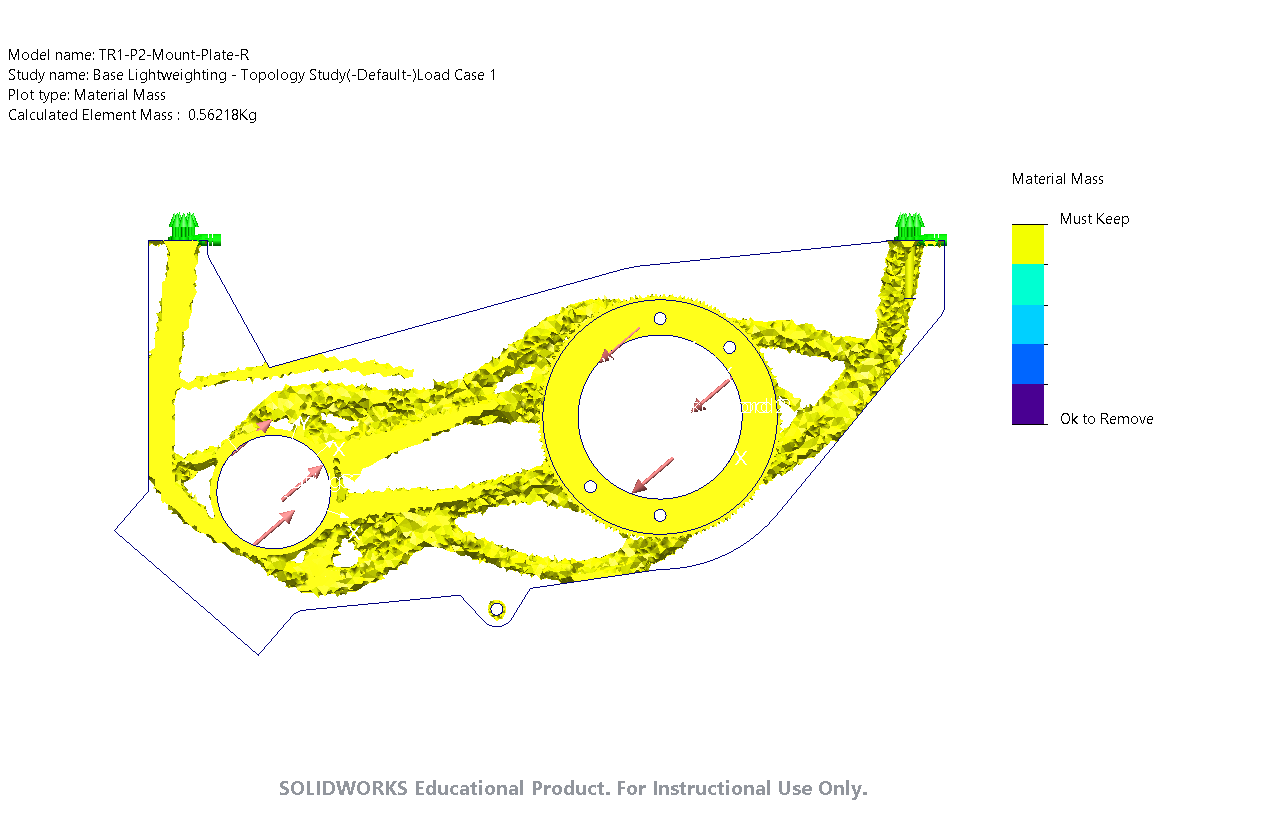

I performed hand calculations to structural integrity under stall torque and peak chain loading. Topology studies influenced initial light weighting. I also checked that my design still had positive margins under the worst-case loading. To gain insight into the strength of my part, I ran a structural simulation in Solidworks Simulation to produce a refined model of the mechanical interactions. Further modal and fatigue Studies were performed to cover all potential failure modes.

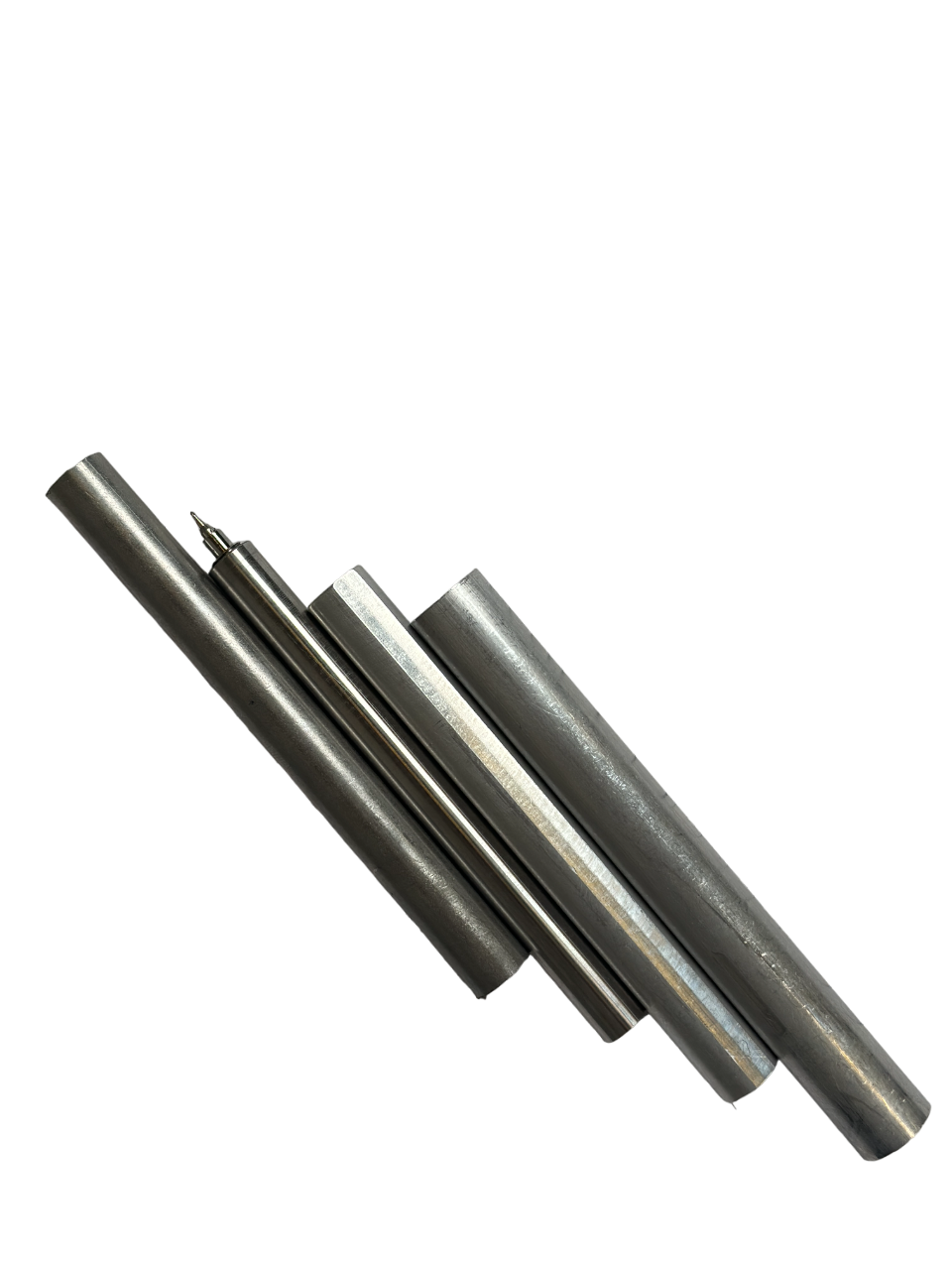

After reaching a design lock on the system, I machined the parts on a waterjet. After removing the light weighted parts, I used a boring head on the mill to bring the bearing holes its final dimensions.