Engineered to Defy Gravity

THE CUBE is purpose-built to balance on a single edge, seamlessly integrating mechanical, electrical, and software systems into a compact and visually striking design. Designed and developed by a team of five students in just four weeks, this project embodies the fusion of mechanical engineering, electronics, and computer science.

Precision Machined and Optimized for Manufacturing

Informed from topology studies, 6061 aluminum plates are light weighted using the waterjet. Utilizing pre-existing holes from waterjetting the light weighted plates are easily secured and milled to create miter joints.

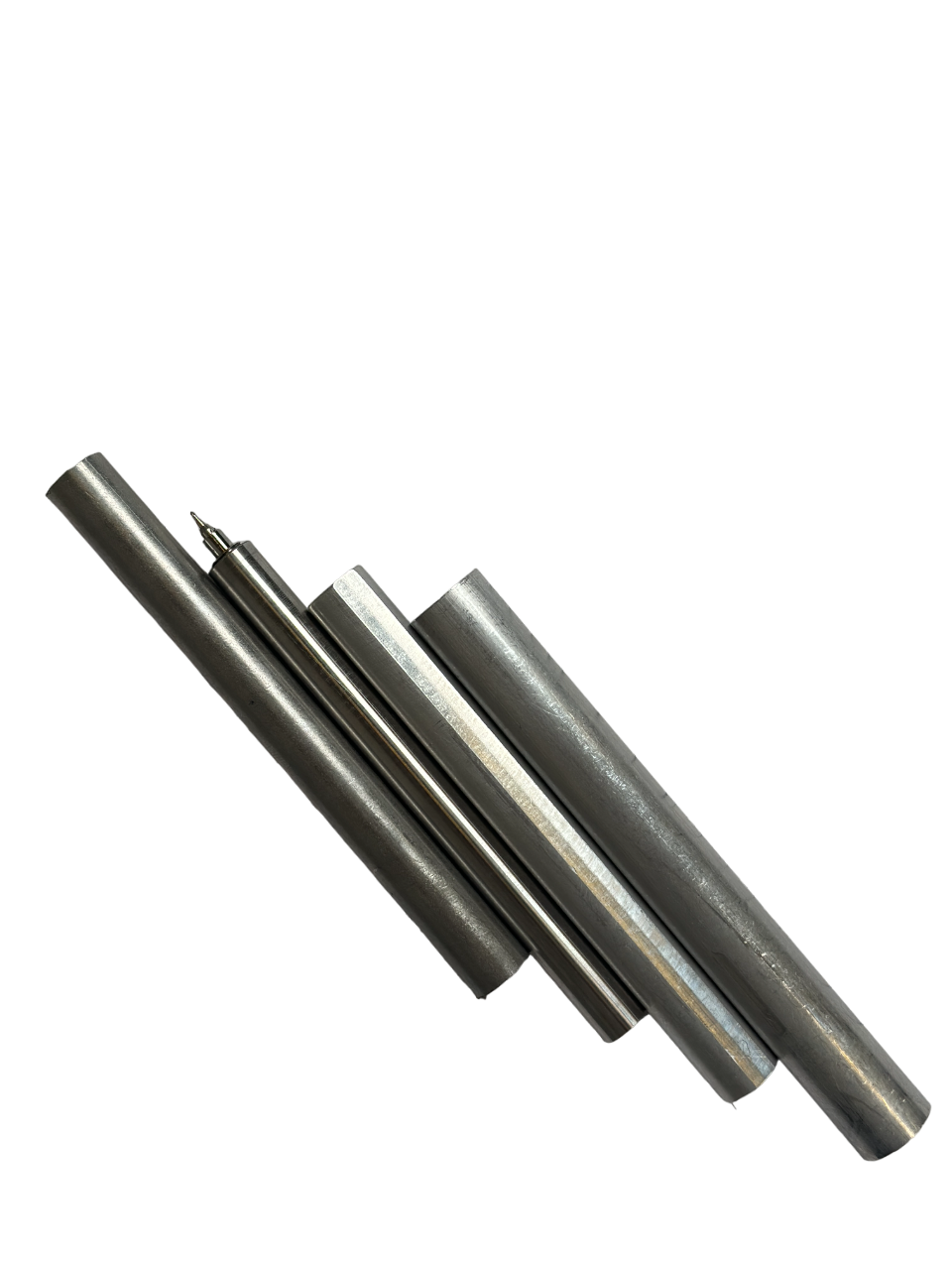

Waterjet steel flywheels maximize moment of inertia, utilizing high-density material for space-saving performance.

Brass motor standoffs are lathed for durability and precision.

Optimized and Intentional Design

Mitered aluminum plates are joined and custom 3D-printed brackets for seamless fitment and ease of assembly.

Magnetic mounting using press-fit stubs enable interchangeable sideplates without compromising aesthetics or functionality

3D-printed mounting for optimal IMU and electronics placement.

Final electronics integrated on a perfboard facilitating robust and clean harnessing.

Every detail, from countersunk holes for a flush finish to the optimized plate light weighting, reflects a commitment to form and function.

Derisked and Modular

Designed to be both 3D printed and machined. Allowing rapid versatile testing and tuning.

Extra motor mounting holes added to support potential enhancements, including balancing on a corner.

For more photos, see The Gallery.